Outdoor 12 24 32 48 72 96 144 Core ADSS Cable G652D Fiber Optic Cable

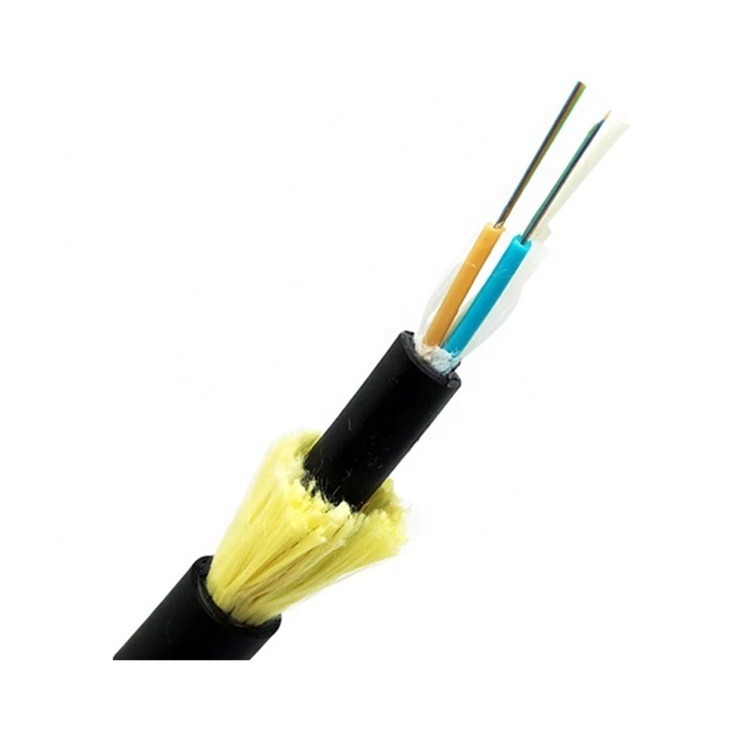

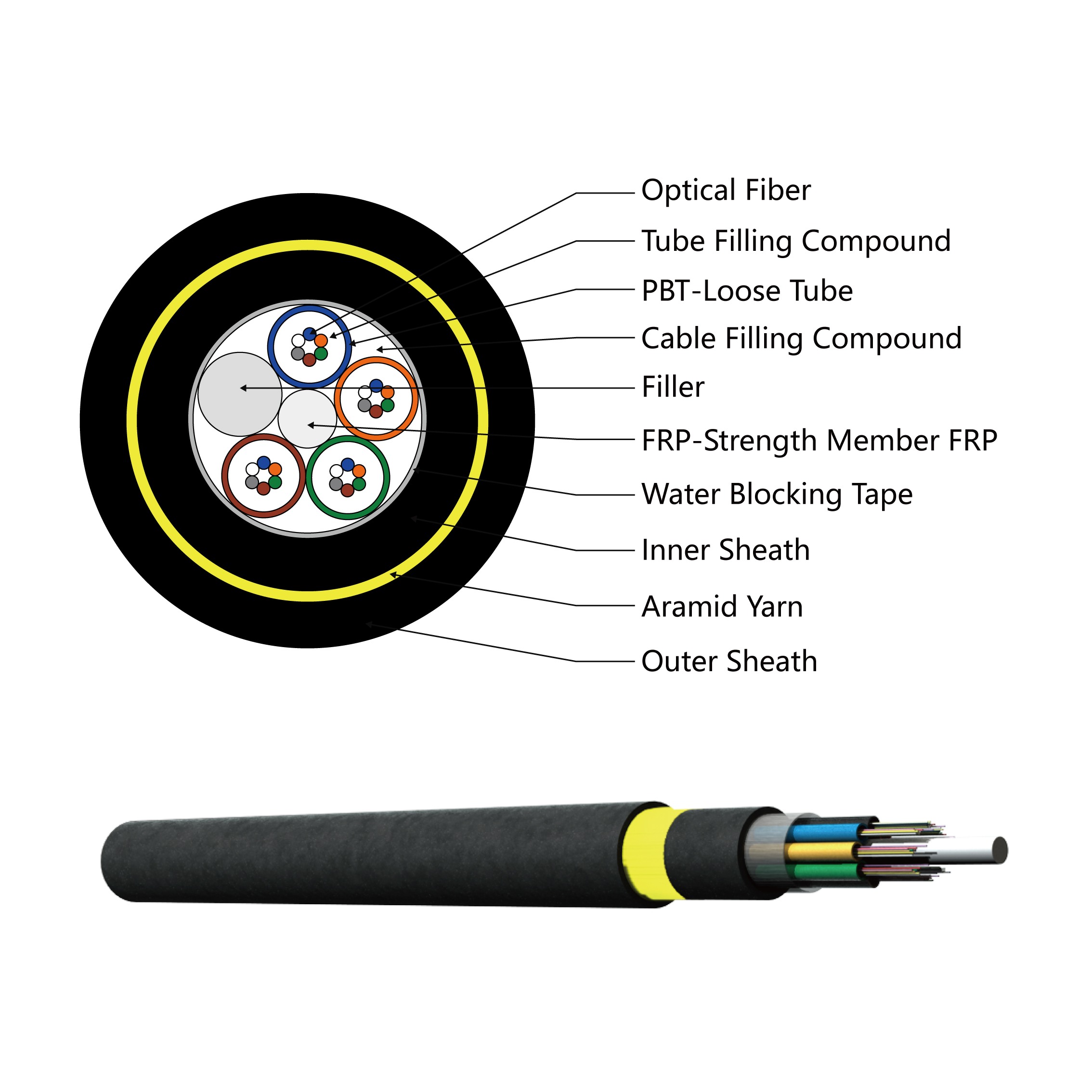

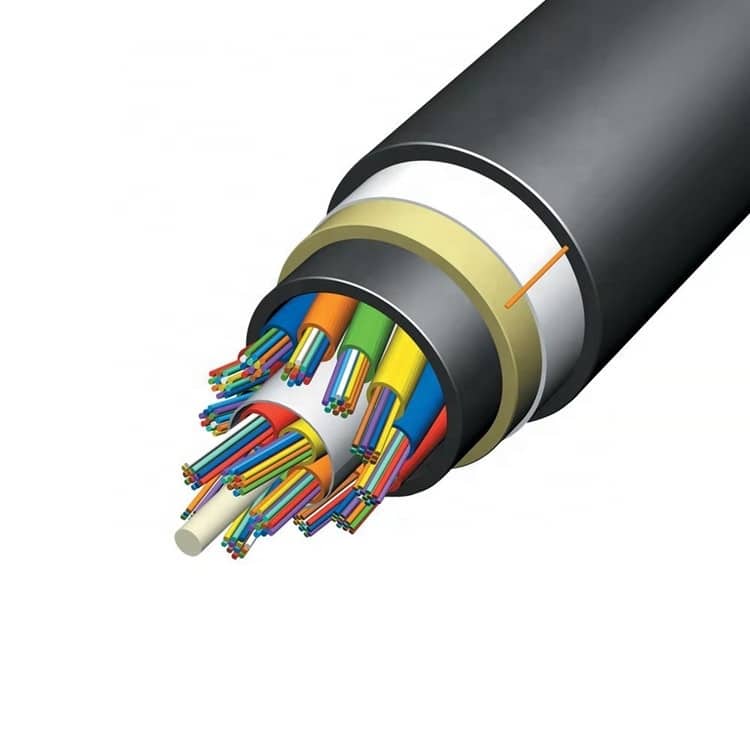

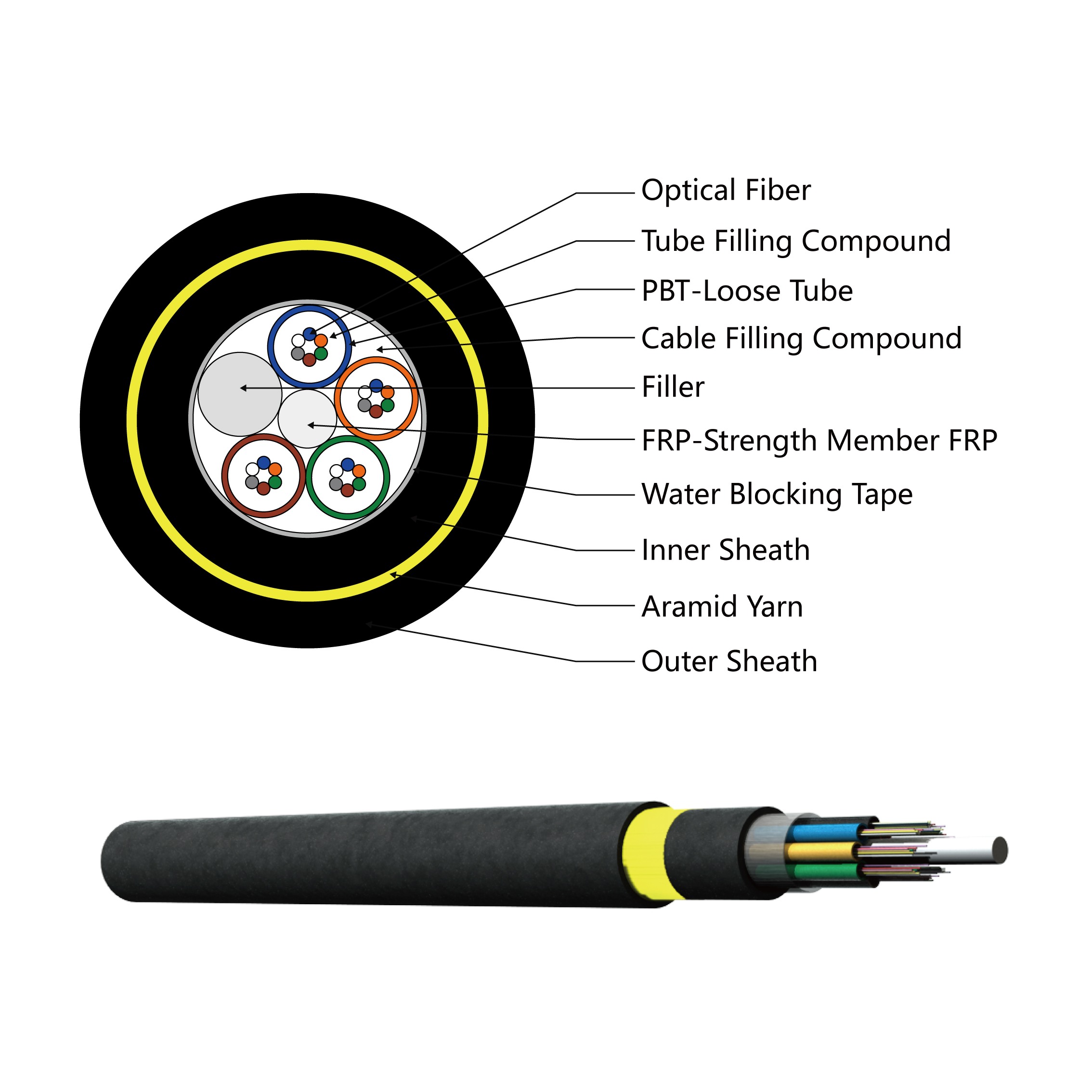

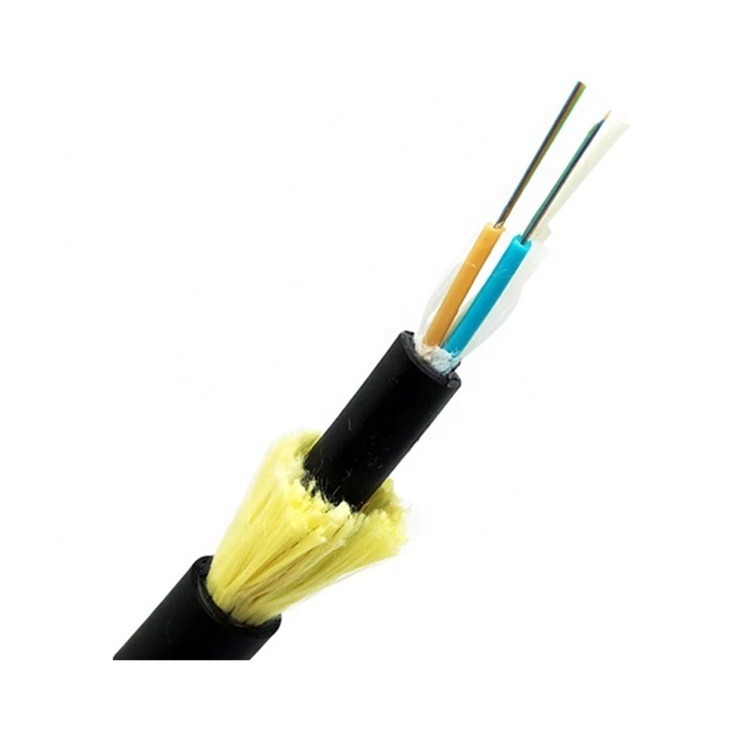

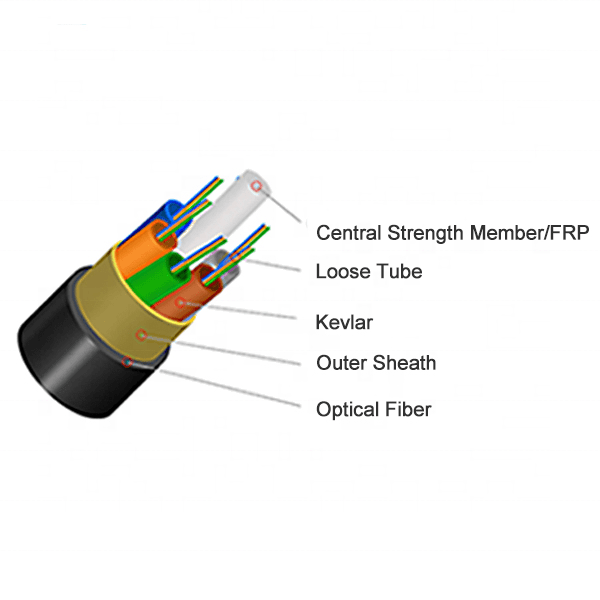

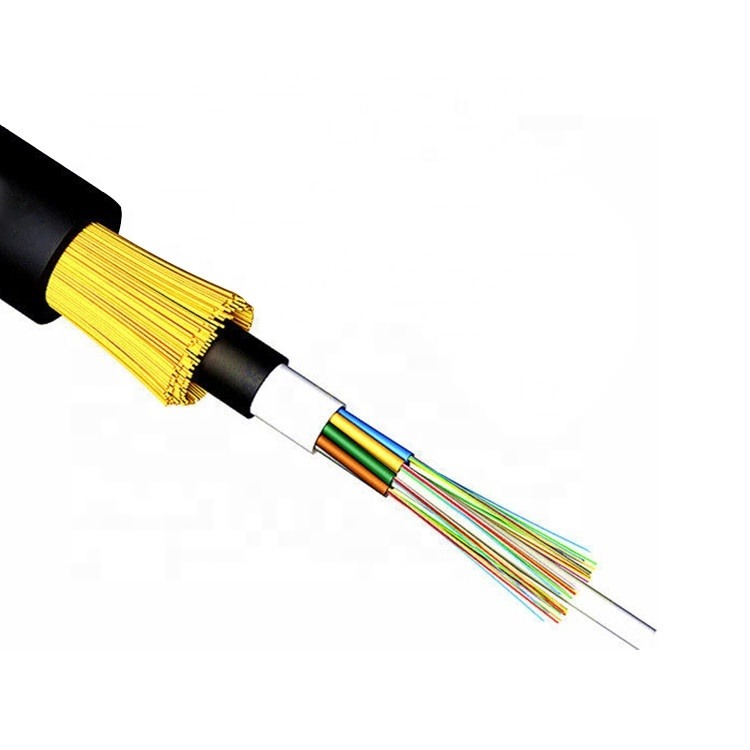

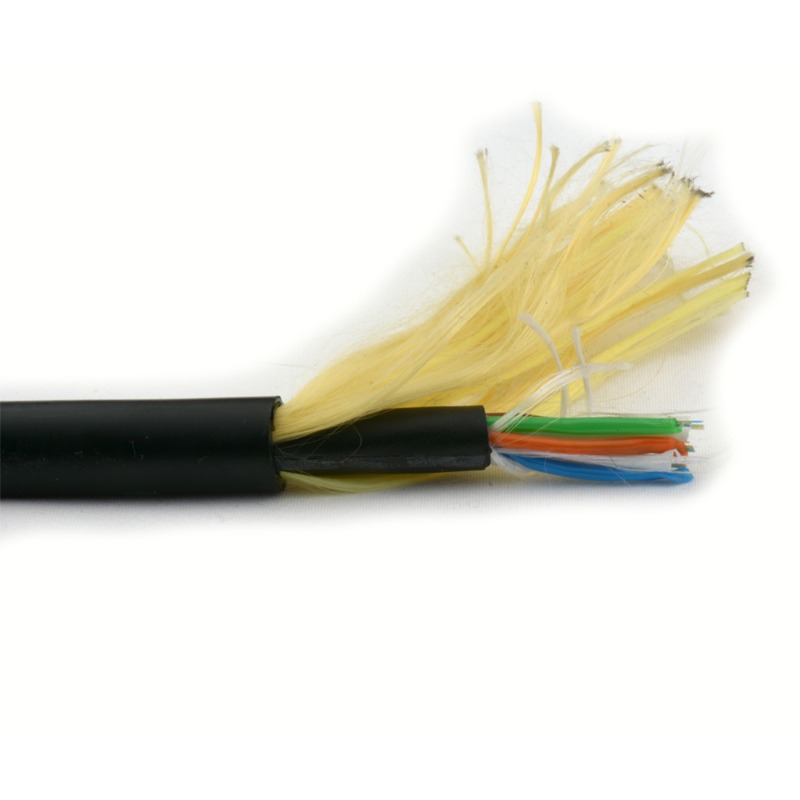

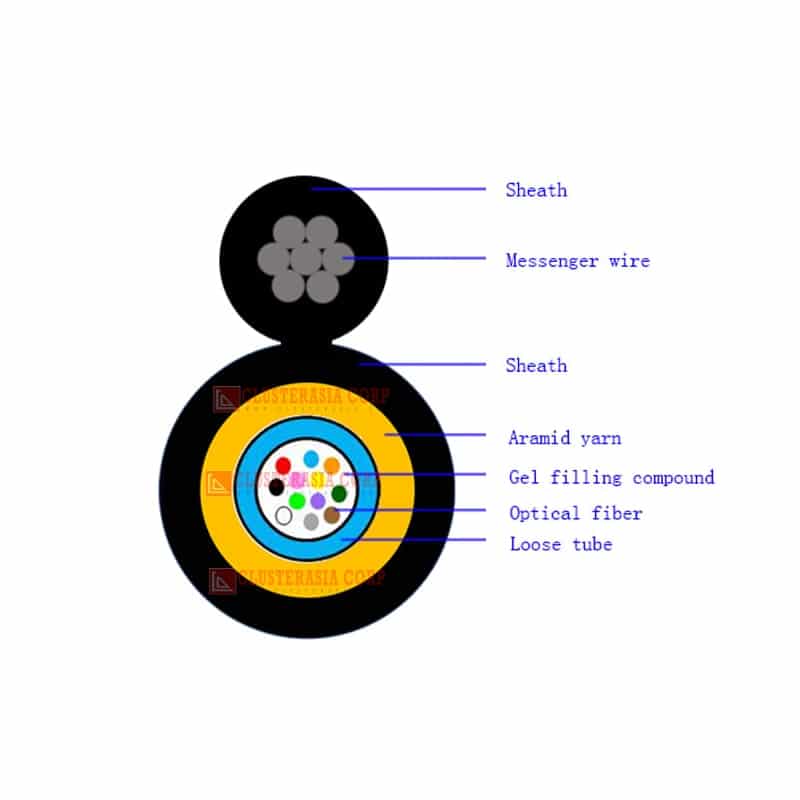

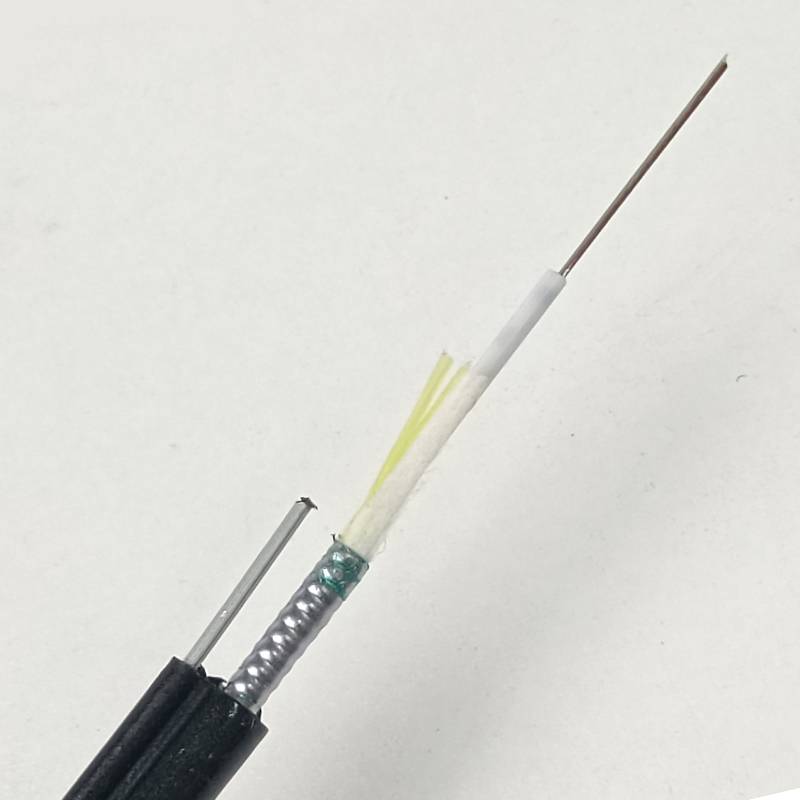

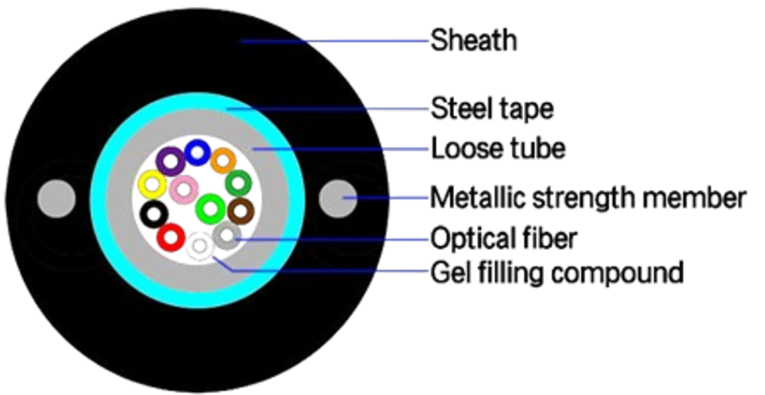

ADSS cable is loose tube stranded. Fibers, 250μm , are positioned into a loose tube made of high modulus plastics. The tubes are filled with a water-resistant filling compound. The tubes (and fillers) are stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core. After the cable core is filled with filling compound. it is covered with thin PE (polyethylene) inner sheath. After stranded layer of aramid yarns are applied over the inner sheath as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

The actual status of overhead power lines is taken into full consideration when ADSS cable is being designed. For overhead power lines under 110kV, PE outer sheath is applied. FOR power lines equal to or over 110kV, AT outer sheath is applied. The dedicate design of aramid quantity and stranding process can satisfy the demand on various spans.

Application

- Outdoor aerial applications

- Low voltage transmission system(≤12 kV)

- Railway & Telecommunication pole route

- Subscriber & Local Area Network

- Voice, data, video & imaging system

Crossing Section

- Can be installed without shutting off the power

2. Light weight and small diameter reducing the load cause -d by ice and wind and the load on towers and backprops

3. Large span lengths

4. Good performance of tensile strength and temperature

5. The design life span is 30 years

6. Package : 2~4km/ wooden drum

SPECIFICATION

| Cable fiber count | / | 2~30 | 32~60 | 62~72 |

| Structure | / | 1+5 | 1+5 | 1+6 |

| Fiber style | / | G.652D |

| Central strength member | material | mm | FRP |

| Diameter (average) | 1.5 | 1.5 | 2.1 |

| Loose Tube | Material | mm | PBT |

| Diameter (average) | 1.8 | 2.1 | 2.1 |

| Thickness(average) | 0.32 | 0.35 | 0.35 |

| Max fiber/loose tube | 6 | 12 | 12 |

| Tubes color | Full color identification |

| Fiber excess length | % | 0.7~0.8 |

| Water resistance | Material | / | Cable jelly |

| Inner sehath | material | mm | MDPE |

| Inner sheath | 0.9mm |

| Non-metallic strengthen components | Material | / | Aramid Yarn |

| Outer sheath | material | mm | MDPE |

| Outer sheath | 1.8mm |

| Cable diameter(average) | mm | 10.9 | 11.5 | 12.1 |

| Cable weight (Approximate) | kg/km | 95 | 110 | 120 |

| Cable Sectional area | mm2 | 93.31 | 103.87 | 114.99 |

| Attenuation coefficient(Max) | 1310nm | dB/km | 0.35 |

| 1550nm | 0.21 |

| Rated Tensile Strength(RTS) | kn | 6 |

| Max allowed tension( MAT) | kn | 2.5 |

| Annual average operating tension (EDS) | kn | 3.2 |

| Young’s modulus | kn/mm2 | 7.8 |

| Coefficient of thermal expansion | 10-6/℃ | 9 |

| Crush resistance | Long term | N/100mm | 1100 |

| Short term | 2200 |

| Permission Bent Radius | static | mm | 15 of OD |

| dynamic | 20 of OD |

| Temperature | When laying | ℃ | -20~+60 |

| Storage and transportation | -40~+70 |

| runing | -40~+70 |

| Scope of application | Suitable for voltage level under 110kV, wind speed below 25m/s, icing 5mm |

| Cable Marks | Company Name ADSS-××B1-PE-100M DL/T 788-2001 ××××M Year

(Or at customer’s request) |

Packing & Delivery

| Fiber | Cable length (KM) | N.W. (kg) | G.W. (kg) | packing size (cm) |

| 2-30 | 2 | 190 | 245 | 100*100*70 |

| 3 | 285 | 345 | 110*110*70 |

| 4 | 380 | 470 | 125*125*90 |

| 32-60 | 2 | 220 | 275 | 100*100*70 |

| 3 | 330 | 390 | 110*110*70 |

| 4 | 440 | 530 | 125*125*90 |

| 60-72 | 2 | 240 | 295 | 100*100*70 |

| 3 | 360 | 420 | 110*110*70 |

| 4 | 480 | 570 | 125*125*90 |

Explore more products when you click here.

You may also like and follow our Facebook Page: Clusterasia Corp. for more updates.

Reviews

There are no reviews yet.